6. Bololi limagwedezeka, ndipo m'lifupi mwa nsonga ya ng'anjo ya malata imatha kusinthidwa kuti muchepetse kuchuluka kwa tini oxidation.

7. 1800mm anawonjezera siteji atatu (anayi) preheating, infuraredi (wotentha mpweya) palokha PID kulamulira kutentha, Ngakhale Kutentha, otetezeka ndi khola

◆ Ndi Lumina (Japan) nozzle, mtundu wa kupopera ndi 20-65mm, kutalika kwa nozzle ndi 50-80mm, ndipo kuthamanga kwakukulu ndi 60ml / min.

◆ Imagwiritsa ntchito fyuluta ya AirTAC (Taiwan), pointer gauge imasonyeza kuthamanga kwa mpweya, mapaipi onse amtundu wa kupopera ndi asidi ndi alkali kugonjetsedwa ndi dzimbiri.

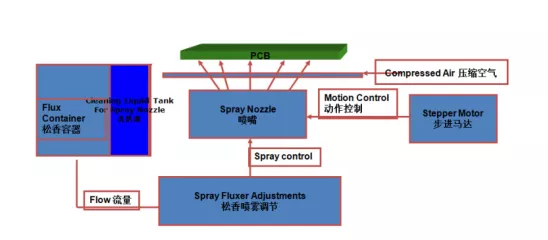

◆ Kupopera mbewu mankhwalawa utenga sikani kupopera mbewu mankhwalawa njira, malire lophimba ndi kulowa maso amaphatikizidwa kulamulira, ndipo PCB ndi basi wapezeka ndi kupopera mbewu mankhwalawa inductive malinga ndi liwiro ndi m'lifupi mwa PCB, kotero kuti wetting osiyanasiyana flux akhoza kukwaniritsa zotsatira zabwino.Mutu wopopera wa inlet ndi ma stepping motor ndi othandiza, okhazikika komanso odalirika.

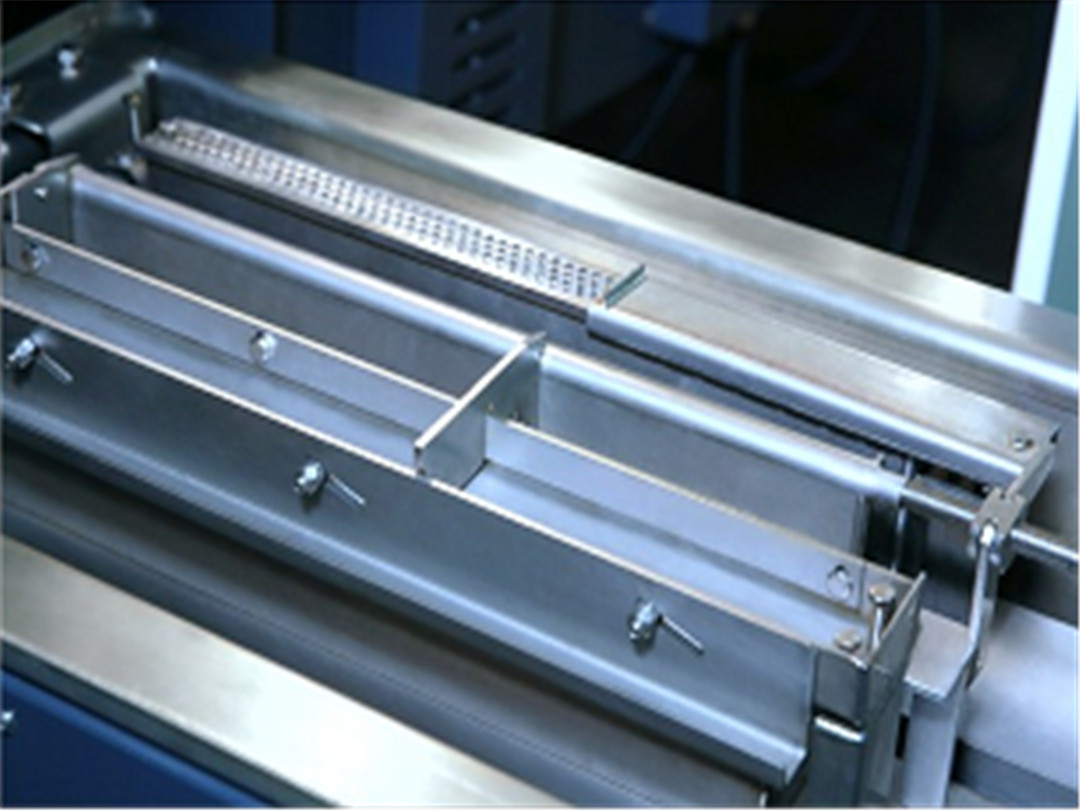

◆ Chitsulo chosapanga dzimbiri chopindika thireyi chimagwiritsidwa ntchito pansi pa mutu wopoperapo poika madzi oipa ndi kutuluka, omwe amatha kuchotsedwa ndikutsukidwa mwakufuna kwake.

◆ Dongosolo lotulutsa mpweya ndi njira yowongoka yokhayo yomwe ili ndi zigawo zitatu za kusefera kwa zitsulo zosapanga dzimbiri zosapanga dzimbiri kuti muchepetse kutsekeka kotsalira kwapaipi yotulutsa mpweya pogwiritsa ntchito mawonekedwe amadzimadzi kuti asefe kuchuluka kwamadzi.

◆ Mpweya wa mpweya wa pneumatic, womwe umawomba madzi ochulukirapo panthawi yopopera mankhwala mu thanki yobwezeretsa kuti asalowe m'malo otentha ndikuwonetsetsa chitetezo chopanga.

◆ Chitsulo chonse chosapanga dzimbiri + aluminium alloy alloy, kuyeretsa kosavuta ndi kukonza, kukana kwamphamvu kwa dzimbiri, kulimba.

Welding System

1. 4mm SUS316L Choyatsira ng'anjo yachitsulo chosapanga dzimbiri, kapangidwe katsopano ka ng'anjo yamoto, mawonekedwe okongola, osavuta kuyeretsa, mbale yotenthetsera yachitsulo, ng'anjo ya ng'anjo simapunduka

2. Kusokoneza wave crest, jet yowongoleredwa, soldering yabwino kwambiri ya zigawo za SMD, ma wave crest ndi osalala ngati galasi

3. M'lifupi mwa nsonga ya mafunde amatha kusinthika kuti muchepetse kuchuluka kwa tini oxidation, ndipo fyulutayo imatha kutulutsidwa popanda kutulutsa mphuno.

4. Wonjezerani chivundikiro cha anti-oxidation pamalo a shaft ya impeller kuti muchepetse kuchuluka kwa tini oxidation chifukwa cha kuzungulira kwa shaft ya impeller

5. The impeller shaft ndi wave motor zitha kupasuka padera popanda kusokoneza njira ya malata (mitundu ina ya ma wave soldering sangathe kupanga izi)

Transport System

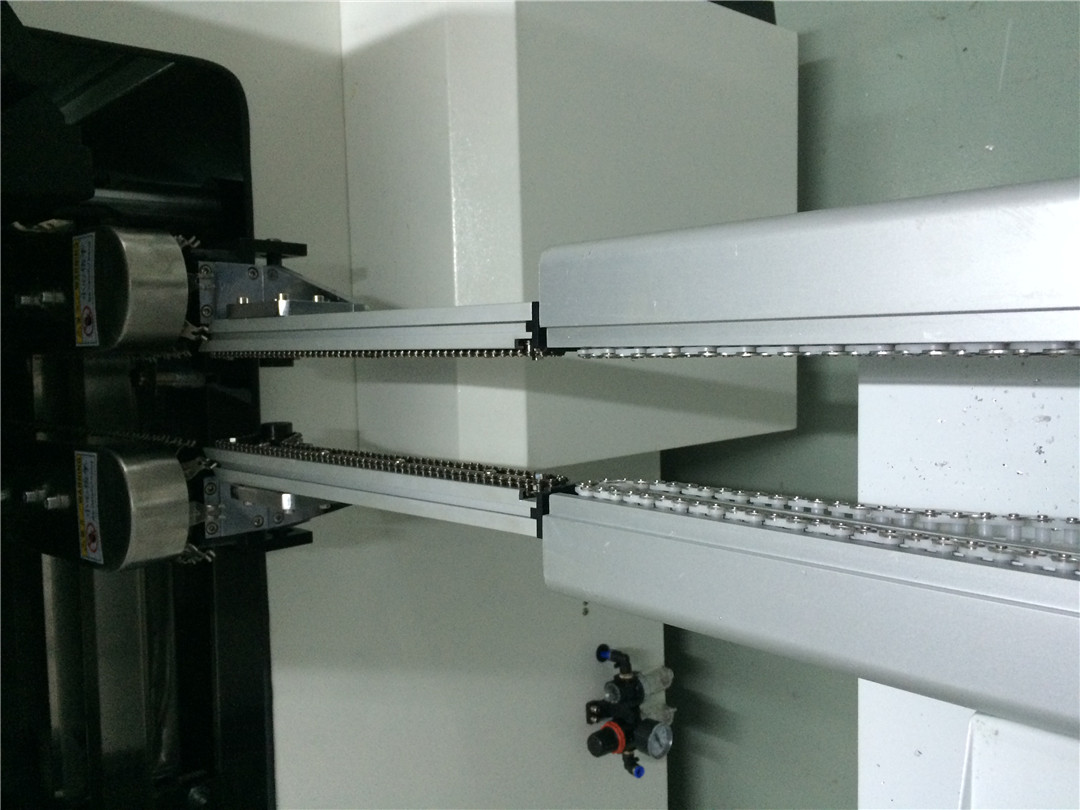

Aluminiyamu choyera chodziwikiratu chodyera ndi cholumikizira chipangizo, kudyetsa kosalala komanso kokhazikika, kusinthika kwakukulu

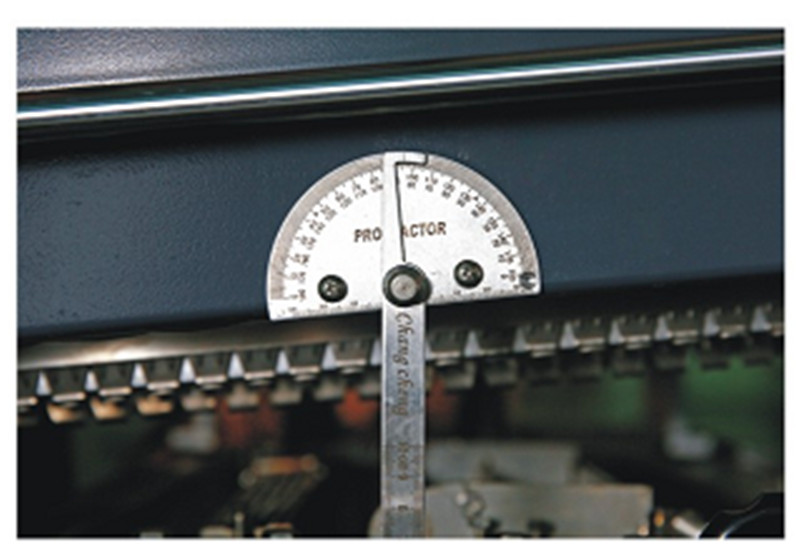

Sitima yowongolera ili ndi chipangizo chake chomwe chimapendekeka, chomwe chimatha kuyang'anira bwino mbali yake ndikuwongolera mawonekedwe a bolodi.

Titaniyamu alloy claw hooks amaonetsetsa kuti malata sadzakhala oipitsidwa, ndipo masitepe atatu owongolera njanji amaonetsetsa kuti njanji zowongolera sizidzawotchedwa, zomwe zimalepheretsa njanji zowongolera kuti zisagwe ndi kupanikizana.

◆ Mkanda wamkuwa wa 4mm umapangitsa kuti kayendetsedwe kake kakhale kosavuta komanso kokhazikika.(Magulu ena ambiri amagwiritsa ntchito zitsulo zosapanga dzimbiri, zomwe sizingatsimikizire kuyenda bwino kwa nthawi yayitali.)

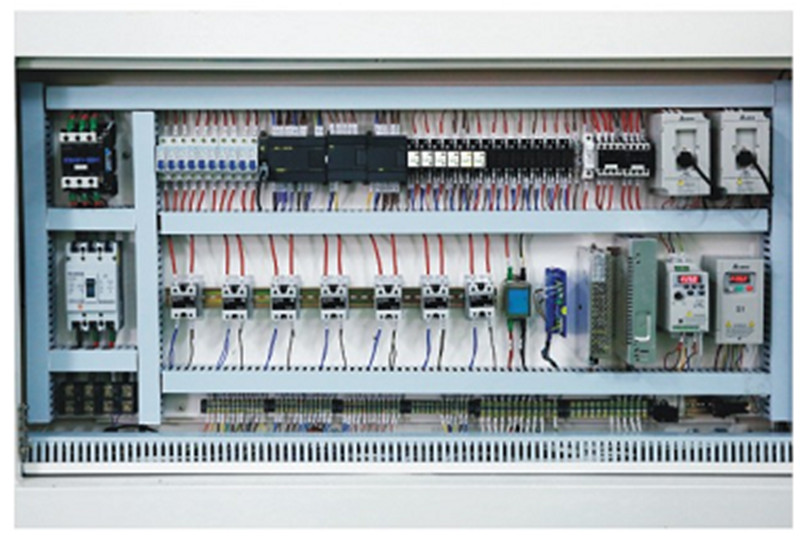

Makina ogwiritsira ntchito osavuta ndi abwino kuti ogwira ntchito azigwira ntchito, ndipo makina owongolera a PC + PLC amapangitsa kuwongolera kutentha kukhala kolondola komanso kokhazikika.

Zida zamagetsi ndizodziwika bwino kunyumba ndi kunja, ndipo choyambirira cha Siemens PLC chimatsimikizira kuti dongosololi ndi lotetezeka komanso lokhazikika.

Kuwongolera kutentha kumatengera kudzipangira nokha PID control aligorivimu, palibe chifukwa chokhazikitsa pamanja magawo a PID, kulondola kwambiri.

Zosintha zaukadaulo

| Chitsanzo | CY-350B/T | CY-450B/T |

| Nambala yamalo otentha | Makina opondera kapena silinda yopanda ndodo | |

| Chiwerengero cha malo ozizira | 6 LITA | |

| Kuthamanga kwa mpweya wa flux | 3-5BAR | |

| Preheating Mode | Mpweya wotentha wocheperako / infrared | |

| Preheating Zone Number | 4 gawo | |

| Preheating Kutalika | 1800 mm | |

| Nthawi Yofunda | Pafupifupi.15min | |

| PCB m'lifupi mwake | 350 mm | 450 mm |

| Atsogolereni osiyanasiyana | 50-350 mm | 50-450 mm |

| Kuthamanga kwa Conveyor | 0-2000mm / mphindi | |

| Kutalika kwa Conveyor | 750 ± 20mm | |

| Mayendedwe amayendedwe | L→R (R→L) | |

| Njira yotumizira | 4-7 ° | |

| Kutentha kwa solder | 9KW (Kutentha kwa chipinda-300 ℃) | |

| Kuchuluka kwa solder | 400Kg | 500Kg |

| Njira yowongolera | Brand Computer (Windowsoperating system)+Siemens PLC | |

| Liwiro la conveyor | 3∮ AC380V 90W, Mtundu: Tai Chuang | |

| Wave motere | 3∮ AC220V 360W * 2pcs, Mtundu: Tai Chuang | |

| Pampu yotsuka zala | 1P AC220V 10W | |

| Zala | Special titaniyamu alloy double groove claw | |

| Njira yozizira | Kuziziritsa mpweya mokakamiza | |

| Mphamvu yamagetsi | 5-waya 3-gawo 380V 50/60Hz | |

| Yambani mphamvu | 38kw pa | |

| Mphamvu yogwira ntchito bwino | Pafupifupi 10Kw | |

| Kutentha kowongolera | Pakompyuta yathunthu ya PID yotseka loop, SSR drive | |

| Alamu yachilendo | Kutentha kwachilendo (kwapamwamba kwambiri kapena kutsika kwambiri pambuyo pa kutentha kosasintha) | |

| Kuwala kwamitundu itatu | Kuwala kwamitundu itatu: kutentha kwachikasu;kutentha kosasinthasintha;zofiira-zachilendo | |

| Kulemera | Pafupifupi. 1800Kg | Pafupifupi.2000Kg |

| Kuyikadimension (mm) | L4300×W1530×H1700mm | |

| Zofunikira za mpweya wotulutsa mpweya | 10 kyubu / mphindi 2 kanjira∮200mm | |