Reflow soldering (reflow soldering / uvuni) ndi njira yomwe imagwiritsidwa ntchito kwambiri pazitsulo zamtundu wa SMT, ndipo njira ina yowotchera ndi yowotchera (Wave soldering).Reflow soldering ndi yoyenera pazigawo za SMD, pomwe ma wave soldering ndi oyenera Kwa pini zida zamagetsi.Nthawi ina ndidzalankhula mwachindunji za kusiyana pakati pa awiriwa.

Reflow Soldering

Wave Soldering

Reflow soldering ndi njira yopangira reflow soldering.Mfundo yake ndi kusindikiza kapena jekeseni mlingo woyenera wa solder phala (Solder phala) pa PCB pad ndi phiri lolingana SMT chip processing zigawo zikuluzikulu, ndiyeno ntchito kutentha mpweya convection Kutentha kwa ng'anjo reflow kutentha malata phala ndi kusungunuka. ndipo anapanga, ndipo potsiriza odalirika solder olowa aumbike ndi kuzirala, ndi chigawo chimodzi chikugwirizana ndi PCB PAD, amene amasewera kugwirizana makina ndi kugwirizana magetsi.Njira yopangira reflow soldering ndi yovuta kwambiri ndipo imaphatikizapo chidziwitso chambiri.Ndi yaukadaulo watsopano wa interdisciplinary.Nthawi zambiri, reflow soldering imagawidwa m'magawo anayi: kutenthetsa, kutentha kosalekeza, kuyambiranso, ndi kuziziritsa.

1. Preheating zone

Preheating zone: Ndilo gawo loyamba la kutentha kwazinthu.Cholinga chake ndi kutentha mankhwala mofulumira kutentha firiji ndi yambitsa solder phala flux.Ndi kupewanso kutentha kwa zigawo zomwe zimadza chifukwa cha kutentha kwambiri kwanthawi yayitali panthawi yomiza ya malata.Njira yotenthetsera yofunikira pakuwonongeka.Choncho, kutentha kwa kutentha ndikofunika kwambiri kwa mankhwalawa, ndipo kuyenera kuyendetsedwa mkati mwazoyenera.Ngati ndi kuthamanga kwambiri, mantha matenthedwe zidzachitika, ndi bolodi PCB ndi zigawo zikuluzikulu adzakhala pansi matenthedwe nkhawa, kuchititsa kuwonongeka.Panthawi imodzimodziyo, zosungunulira mu solder phala zidzasungunuka mofulumira chifukwa cha kutentha mofulumira.Ngati ndi pang'onopang'ono, solder phala zosungunulira sangathe volatilize mokwanira, zomwe zidzakhudza soldering khalidwe.

2. Kutentha kwanthawi zonse

Kutentha kwanthawi zonse: cholinga chake ndikukhazikitsa kutentha kwa gawo lililonse pa PCB ndikufikira mgwirizano momwe mungathere kuti muchepetse kusiyana kwa kutentha pakati pa zigawozo.Panthawi imeneyi, nthawi yotentha ya chigawo chilichonse ndi yaitali.Chifukwa chake ndi chakuti zigawo zing'onozing'ono zidzafika pofanana poyamba chifukwa cha kutentha kochepa, ndipo zigawo zazikulu zidzafunika nthawi yokwanira kuti zigwirizane ndi zigawo zing'onozing'ono chifukwa cha kuyamwa kwakukulu kwa kutentha.Ndipo onetsetsani kuti flux mu solder phala ndi volatilized kwathunthu.Panthawi imeneyi, pansi pa mphamvu ya flux, oxides pa mapepala, mipira ya solder ndi zikhomo zamagulu zidzachotsedwa.Panthawi imodzimodziyo, flux idzachotsanso mafuta pamwamba pa zigawo ndi mapepala, kuonjezera malo a soldering, ndikulepheretsa kuti zigawozo zisakhalenso oxidized.Gawoli likatha, gawo lililonse liyenera kusungidwa pa kutentha komweko kapena kofananako, apo ayi pangakhale kusokonekera koyipa chifukwa cha kusiyana kwakukulu kwa kutentha.

Kutentha ndi nthawi ya kutentha kosalekeza kumadalira zovuta za mapangidwe a PCB, kusiyana kwa chigawo cha mitundu ndi chiwerengero cha zigawo, kawirikawiri pakati pa 120-170 ° C, ngati PCB ndi yovuta kwambiri, kutentha kwa nthawi zonse kutentha kwa zone. ziyenera kutsimikiziridwa ndi kutentha kofewa kwa rosin monga chofotokozera, cholinga chake ndi Kuchepetsa nthawi ya soldering m'dera lakumbuyo-kumapeto, malo otentha a kampani yathu nthawi zambiri amasankhidwa pa madigiri 160.

3. Reflow zone

Cholinga cha reflow zone ndi kupanga solder phala kufika kusungunuka ndi kunyowetsa mapepala pamwamba pa zigawo zikuluzikulu kuti soldered.

Pamene bolodi la PCB likulowa m'dera la reflow, kutentha kudzakwera mofulumira kuti phala la solder lifike kusungunuka.Malo osungunuka a phala la lead solder Sn: 63 / Pb: 37 ndi 183 ° C, ndi phala lopanda kutsogolo Sn: 96.5 / Ag: 3 / Cu: Malo osungunuka a 0.5 ndi 217 ° C.M'derali, kutentha komwe kumaperekedwa ndi chowotchera kumakhala kochuluka kwambiri, ndipo kutentha kwa ng'anjo kudzayikidwa pamwamba kwambiri, kotero kuti kutentha kwa solder phala kudzakwera kutentha kwambiri mofulumira.

Kutentha kwapamwamba kwa reflow soldering curve nthawi zambiri kumatsimikiziridwa ndi malo osungunuka a solder phala, bolodi la PCB, ndi kutentha kosagwira kutentha kwa chigawocho chokha.Kutentha kwapamwamba kwa chinthucho m'dera la reflow kumasiyanasiyana malinga ndi mtundu wa solder phala logwiritsidwa ntchito.Nthawi zambiri, palibe Kutentha kwapamwamba kwambiri kwa phala la lead solder nthawi zambiri kumakhala 230-250 ° C, ndipo phala la lead solder nthawi zambiri ndi 210-230 ° C.Ngati kutentha kwapamwamba kumakhala kochepa kwambiri, kungayambitse kuwotcherera kozizira komanso kunyowetsa kosakwanira kwa ma solder;Ngati ndipamwamba kwambiri, magawo amtundu wa epoxy resin adzatero Ndipo gawo la pulasitiki limakonda kupaka, PCB kuchita thovu ndi delamination, komanso kumapangitsa kuti pakhale zitsulo zambiri za eutectic, zomwe zimapangitsa kuti ma solder awonongeke, kufooketsa mphamvu zowotcherera, ndi kukhudza makina a mankhwala.

Izo ziyenera anatsindika kuti flux mu solder phala m'dera reflow ndi zothandiza kulimbikitsa wetting wa solder phala ndi solder mapeto a chigawo chimodzi pa nthawi ino, ndi kuchepetsa mavuto pamwamba pa solder phala.Komabe, chifukwa chotsalira cha okosijeni ndi zitsulo zam'madzi mu ng'anjo ya reflow, Kukwezeleza kusinthasintha kumakhala ngati cholepheretsa.

Nthawi zambiri kutentha kwa ng'anjo yabwino kumayenera kukumana ndi kutentha kwakukulu kwa mfundo iliyonse pa PCB kuti ikhale yosasinthasintha momwe mungathere, ndipo kusiyana kwake kuyenera kusapitirira madigiri 10.Ndi njira iyi yokha yomwe tingatsimikizire kuti ntchito zonse za soldering zatha bwino pamene mankhwala alowa m'madera ozizira.

4. Malo ozizira

Cholinga cha zone yozizira ndikuziziritsa mwachangu tinthu tating'onoting'ono ta solder, ndipo mwachangu kupanga ma solder owala okhala ndi arc pang'onopang'ono komanso malata athunthu.Choncho, mafakitale ambiri adzalamulira malo ozizira, chifukwa amathandiza kupanga mapangidwe a solder.Nthawi zambiri, kuzizira kwambiri kumapangitsa kuti phala losungunula lichedwe kwambiri kuti lizizire komanso kuti likhale lotchingira, zomwe zimapangitsa kuti zisamalire, kunoledwa ngakhalenso ting'onoting'ono tomwe tapanga solder.Kutsika kozizira kwambiri kumapangitsa kuti pamwamba pa PCB pad pamwamba pakhale zinthu zomwe zimasakanizidwa mu solder phala, zomwe zimapangitsa kuti zolumikizira zogulitsira zikhale zovuta, zopanda kanthu komanso zolumikizira zakuda.Komanso, magazini onse zitsulo pa soldering malekezero a zigawo zikuluzikulu zidzasungunuka mu soldering olowa, kuchititsa soldering malekezero a zigawo zikuluzikulu kukana nyongolotsi kapena osauka soldering.Zimakhudza khalidwe la soldering, kotero kuzizira kwabwino kumakhala kofunikira kwambiri pakupanga mgwirizano wa solder.Nthawi zambiri, ogulitsa phala la solder amalimbikitsa kuzizira kwa solder kwa ≥3°C/S.

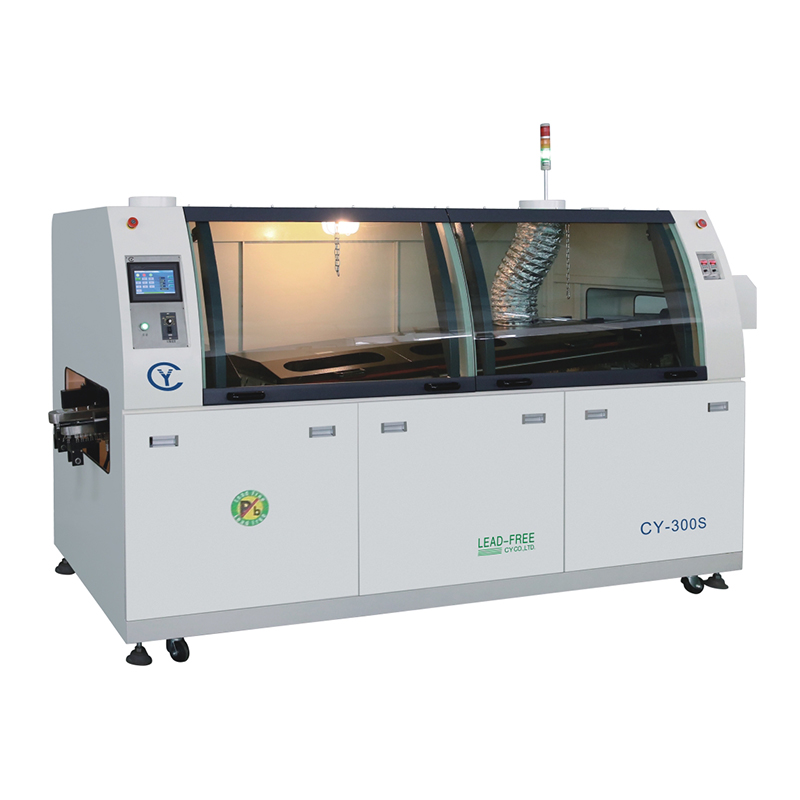

Makampani a Chengyuan ndi kampani yomwe imagwira ntchito popereka zida za SMT ndi PCBA.Imakupatsirani yankho labwino kwambiri kwa inu.Ili ndi zaka zambiri zopanga komanso zofufuza.Akatswiri aukadaulo amapereka malangizo oyika komanso kugulitsa khomo ndi khomo, kuti musakhale ndi nkhawa.

Nthawi yotumiza: Mar-06-2023